Beginning life as a subcontractor of Hyundai Heavy Industries, Seho Engineering is now pioneering the marine transportation sector in the Korean market with its major activities including: offshore plant design, heavyweight structure transportation, bridge construction, special marine equipment design, etc.

By utilizing midas NFX for large structural analysis, Seho Engineering was able to expand their expertise not only into shipbuilding and civil engineering, but onto machineries as well.

A good tool for large structural analysis

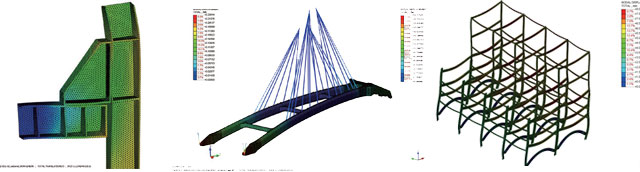

Marine transportation engineering requires CAD and CAE solutions for comprehensive structural analyses: not only linear static analysis, but also nonlinear, vibration and other advanced analysis functions.

There has also been an increase in the demand for 3D simulation. When it comes to designing structures of special shapes, a simple 2D drawing is not sufficient. To cope with the demands of the market, Seho Engineering has been seeking a way to strengthen its ability in structural analysis.

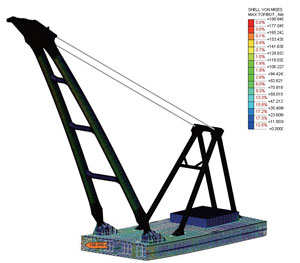

“In the company we were using software packages that were more specialized in ship building and marine technologies, such as PATRAN, NASTRAN, ALGOR, SACS, OPTIMOOR, KST-SHIP etc. To expand our business into general structures and machineries, we adopted midas NFX in 2009. And it has been well used in the company for mechanical analyses of cranes, special equipment etc.”

“I was expecting some difficulties implementing NFX into the team, as it was a relatively new tool, but the swift adoption of the software was a great surprise. The theoretical parts of the CAE tools are the same, and NFX provides an intuitive working environment. After a mere two days of training, our engineers could easily navigate through the NFX interface,” Said deputy director Wook-dong Lee.

“One of the biggest improvements that we have made, after using NFX, is the mesh generation. For a complex structure such as a crane, which contains many complicated geometries and curved surfaces, it used to take us 15 to 30 days to build the meshed model. With midas NFX we are able to complete this work in a week, or even in as short as 3 days.”

“It is common practice today to automatically generate meshes and build the FE model based on CAD data. But generating a high-quality FE model requires high accuracies in the CAD data recognition and the auto-mesh generation. We are very satisfied with midas NFX for this matter. The model quality is excellent and the error occurrences have decreased a lot compared to past experiences.”

The CAD file sizes for large-scale structures are quite big, which leaves them prone to errors when converted. Engineers needs to manually correct these errors when performing automatic mesh generation in CAE tools. This correction work can become a hassle if the software does not have a developed geometry / mesh modifying interface. With midas NFX, we don’t have that problem as the simple interface is equipped with all the required tools. We are able to cut the time on this task by 10-20%.

A variety of analysis functions are needed to analyze crane structures such as: deformation analysis during salvaging, contact analysis of bolt connecting parts, structural analysis of upper body, etc. Additionally, due to the large size of the geometry and its data, we used to simulate each part separately and combine the data together. But sometimes unexpected errors occur during the data combination, for example, the loss of assigned properties. With midas NFX it is now possible to analyze the entire system of large structures. Errors are prevented!

An agile business relies on excellent technical support

“Since Seho Engineering operates in the shipbuilding area, we have technical support requests not only in the mechanical area, but also in the civil and architectural engineering areas. This is one of the extra bonuses of choosing midas NFX. MIDAS IT is, at the same time, a world class software provider for civil engineering. This does help to facilitate the communication,” explained Lee. “Besides, midas NFX has excellent technical support, the feedback is quick, usually in as short as one or two days. People are always friendly and helpful and for a small sized company such as Seho engineering, the agility to respond to clients’ requests is very important. The high standard of technical support is one of the main reasons that we have chosen midas NFX.”

The future holds in a common vision of 3D CAD-CAE-Graphic integration

“3D design will soon become the mainstream in shipbuilding and civil engineering, but we are still in a transitional period, when 3D models are used merely as visual aids while 2D blueprints are used in actual designs and construction. This is gradually changing with the development of 3D modelling technology and Seho Engineering is keen to become more involved in the implementation of 3D design and the integration of CAD-CAE-Graphic technology. It’s important that the vision of MIDAS IT aligns with our expectations. We see huge potential in midas NFX and we expect to apply it into multiple engineering fields, such as civil and marine engineering.”

|