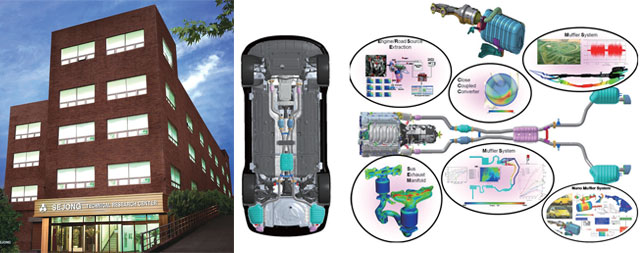

Founded in 1976, SEJONG Industries is specialized in the design and manufacture of automotive exhaust systems. It develops 60% ~ 70% of exhaust system parts for two major Korean automotive brands, Hyundai and KIA. SEJONG Industries has since the time pioneered in international markets such as in China, Russia, Czech Republic, Slovakia, and India. Through the introduction of midas NFX, SEJONG Industries was able to significantly reduce produce developing time, not only through professional analysis but also through the fact that designer can now perform pre-manufacturing analysis efficiently.

Pressing Demand for Rapid Product Development

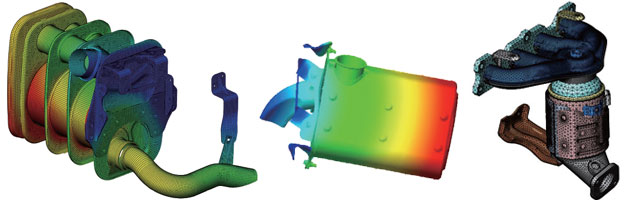

SEJONG Industries has been radically investing more than 10 billion KRW in facilities to maximize their technical capabilities, thus strengthening their global competitiveness. The R&D department consists of structural design/analysis/test/execution teams, who are putting their efforts into developing a design-analysis process for exhaust systems. The crucial analyses include structural, vibration, noise, fluid, etc.

The head of R&D department, Minchul Chun, explained that “Development time for new car models has been highly reduced in the past few years. Consequently, we need to reduce our own development time too, in order to meet this high demand from our clients (automotive companies). CAE analysis plays a significant role in this. On one hand, it serves as an alternative to replace the real object testing, which costs more time and money. On the other hand, by discovering structural problems in early stage of the design, we can reduce the number of design iterations, thus reduce the development time.” He added that “Various analysis tasks are needed, such as thermal stress, fluid, structural and fatigue analysis. We need a fast and effective procedure to implement these different analysis functions. Time reduction is our first priority. If the time required for analysis is longer than the time required for testing, despite the huge reduction of costs, it is considered as ineffective. Additionally, we don’t think the processes of testing and analysis are separated. Instead we should consider integrate the two methods and apply them extensively.”

A Tool That Extend Designer’s Capability

SEJONG Industries had continuously been looking for a CAE program that would optimize the CAE process based on their requests. One of the major requests is that they needed to examine the models in the early stages of design. “We were searching for a CAE program that could work as a tool not only for FEA analysts but also designers. They we found midas NFX. After the initial testing period, they were able to introduce NFX into our working environment in 2009.“

The reason SEJONG Industries chose NFX was because of its user-friendliness that made it more accessible for designers. “The fact that it allowed both analysts and designers to share an FE Model and use it for their tasks immediately attracted us. Designers have very special requests for CAE tools. Since their main task is designing rather than performing analysis, they are expected to do a quick analysis with the least amount of time spent,” Chun explained. “With the prior analyst-oriented CAE tools, it was not easy for designers to get a hold of all the functions, therefore they were only able to use them for the simplest tasks. However, with midas NFX, the range of what a designer can do has been extended significantly. “

A Tool That Meets the Needs of Every Role in the Team

Through the implementation of midas NFX, SEJONG industries was able to build an efficient analysis process. “Thanks to the user-friendly working environment equipped with automated wizards and reporting features, designers are no longer bothered with tedious tasks. If a designer wants to test different designs, they can just change the required parts and perform the analysis by himself.” Chun explained the improvements in designers’ work.

“The analysts are happy with the implementation too. With the primary examination of the concept model being performed by the designer, 50% of the amount of tasks of the analysts have been reduced. They have more time to focus on their high-end analyses. The analysts can also benefit from the automated functions. With the auto-contact function only, they have reduced the time of pre-processing by 70%. Our engineers love the mesher too, which improves the mesh quality and reduce the mesh generation time”

“To add in further, some designer-oriented CAE programs have limited analysis capacities, and to be used together with another program, there are always some compatibility issues. With fully developed analysis capacities, NFX is not required to be used along with other programs, therefore the amount of tasks have been minimized.”

Searching for Automated Process for Multidisciplinary Integrated Analysis

SEJONG industries plans to upgrade the current analysis process and extend it to an integrated automation process for multidisciplinary fields. “Designers need to upgrade the amount of information they have regarding all fields” is the mind-set applied to encourage designers to gain more in-depth knowledge about their products.

“We provide one training course per quarter and regular technical sessions for designers. An analysis guide is under construction too. On the other side, a plan to automate the links to other programs for analysts is under development. “

About the automation plan, SEJONG industries seems to discover another perspective. Chun says “The automation of a single software for a single field exists, while the automation of multiple software programs for multidisciplinary fields exists, but NFX is something different. Through API, NFX has the strength to integrated multidisciplinary analyses in one single interface. We believe that NFX has the potential to replace some of the high price solutions in our automation plan”.

|