With 8 corporate offices in Korea and 15 offices abroad, Hwaseung R&A is a leading company in both the Korean and International market for the development and manufacture of automobile hoses and weather strips. It has recently started developing a vibration analysis process, with the purpose of taking their product development to another level.

Sang-Ryul Han, head of FL Design team, introduced “Hwaseung R&A is one of the 2 companies involved in the manufacturing of brake hoses in South Korea, and the only one that can develop air-conditioning hoses and perform vibration analysis as well.” He also proudly called his company as, “an all-in-one company that gets a nice proportion of the action in the marketplace.”

With additional processes for vibration analysis added, product development continues…

With the attention of automotive industries shifting towards noise and vibration reduction, car manufactures become more sensitive to relevant subjects and start to propose higher demand. Hwaseung R&A has been doing research on how to optimize rubber condition to reduce vibration for a long time, and recently developing a process for vibration analysis has been added as a priority to the agenda.

“We have several software programs in the company to carry out different analysis tasks, but we need something better, something exceptional for vibration analysis. After searching for a while, we encountered midas NFX. We were very cautious about the choice. We had been trying and benchmarking NFX for 6 months, and finally we decided it was the right tool and introduced it to our working environment,” Han explained. “More expensive tools could have been purchased according to our budget, however NFX seemed to be a more effective choice. The result showed it too. NFX was easily introduced to the work, thanks to the full support of midas NFX team.”

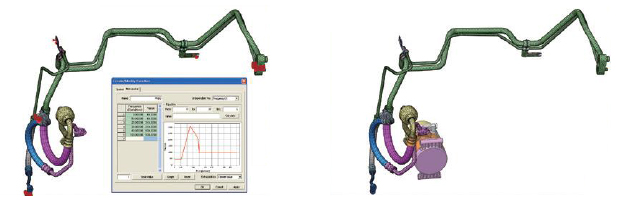

“’A user friendly tool that creates a seamless experience from importing the CAD model, to preparing the analysis model, to assigning the analysis conditions’ is how our engineers have described NFX. We are using NFX as the main software for vibration analysis in air conditioning host projects”

Workload required for design changes has been reduced by 50%

After the implementation of new process for vibration analysis, there was a huge change made with the reduction of tedious tasks and workloads along with an enhancement in quality, leading it to be considered a reliability to use NFX.

“For brake hose development projects, 70~80% of the work is introduced by design changes. Since it is a product that prioritizes safety standards, the design needs to go through 500,000 cycles of testing, which usually take 7~10 days. When design changes are involved, the whole process is done over and over again costing a lot of time and money.”

"After NFX is introduced to carry out vibration analysis, designers have more confidence on their design results, their design quality becomes better and their workload is cut into half." Han stated that, “It is significant that we can optimize the design before sending it to manufacture. We have never done something like this before.”

“Through simulation, we can see the results through our own eyes and communication is made a lot smoother, which leads to an increase in the oversea business,” Han explained. “When it comes to persuading the clients, nothing works better than showing their directly our technical strength.”

“Buyers are already aware of the manufacturing process. The only technical aspect that can be seen is the analysis, so this becomes our first step to improve our communication with clients. At the beginning, there were many doubts regarding whether we should show the vibration analysis results during a technical presentation to our clients, but soon it was proved to be an effective communication method. With analysis results, we are able to show not only company’s technical strength, but also our commitment to provide better service. As a result, more and more orders from oversea clients are coming in.”

|